Our Services

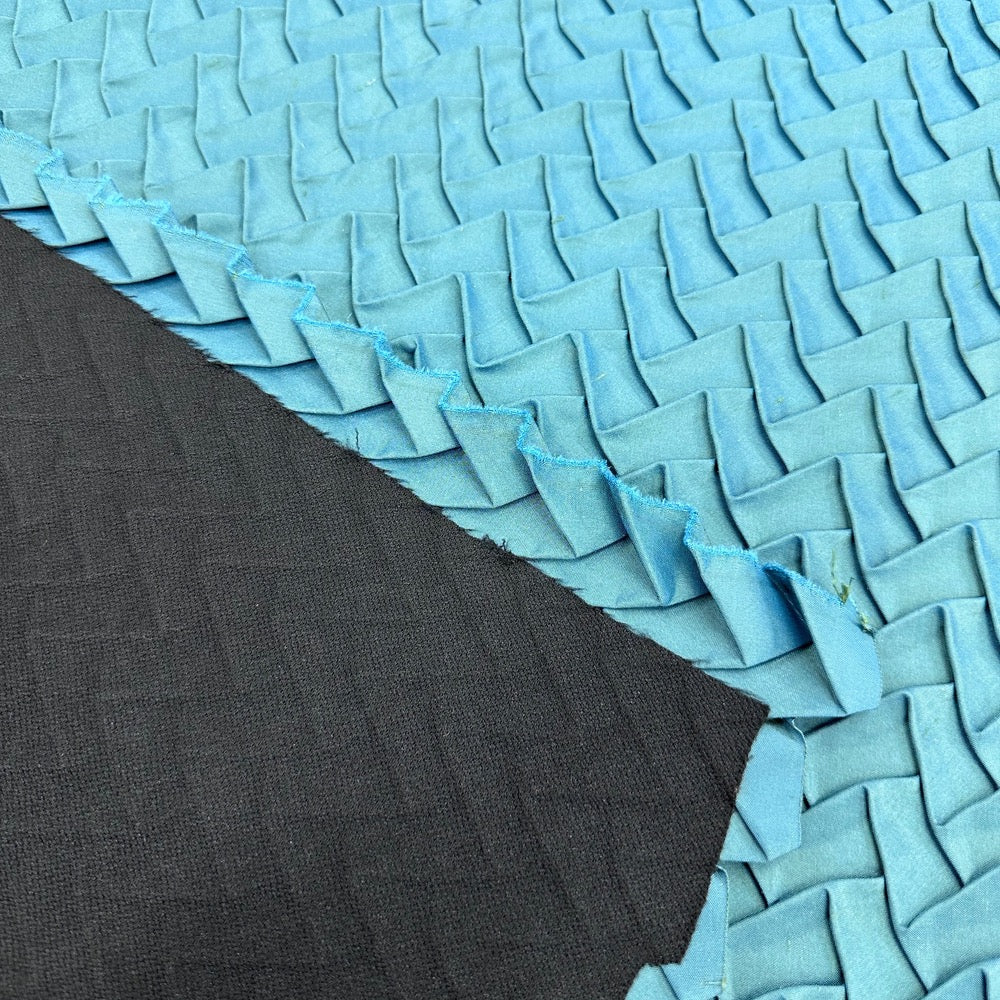

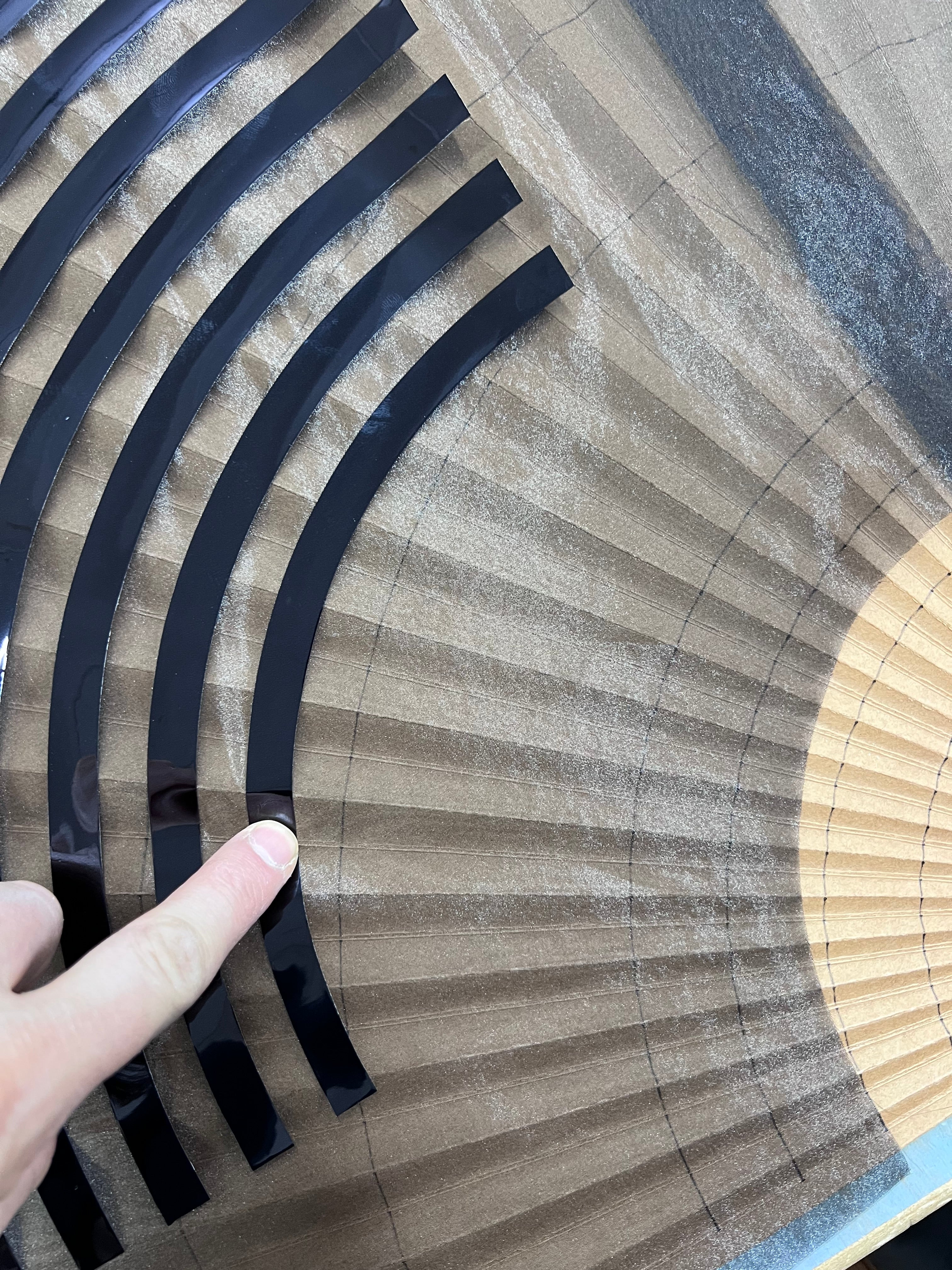

Pleating

For nearly a century, International Pleating has concentrated on the art of textile pleating and fabric texturizing. There are several methods used for professional pleating. The two most prevalent we use are machine and pattern pleating. Machine pleating is a process whereby fabric by the roll is fed into a machine that systematically folds it. The machines we use are the most precise pleating machines in the world that are manufactured in Germany. We are the only pleaters in the United States to possess such machines.The second most common method we use ispattern pleating; also referred to as “hand” or “table” pleating. This processes is done by placing fabric in a mold then exposing to steam. This type of pleating is usually done for specific results. It is pleated by the panel at various lengths, usually between 1 to 4 yards.

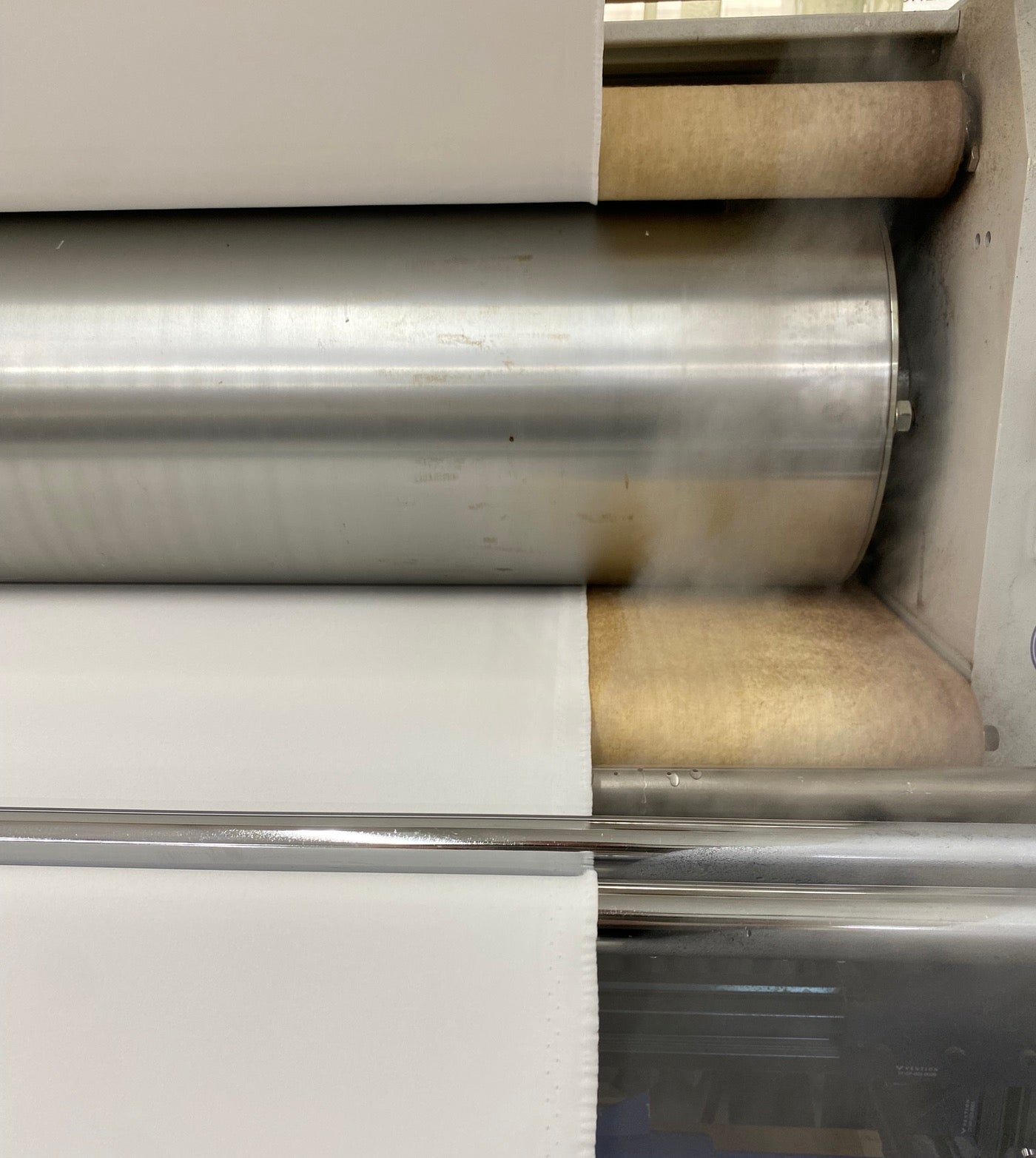

Fusing/ Bonding

Another service that we provide is fabric fusing. This process is beneficial to pleated as well as non-pleated fabrics. Fusing adds body to plain fabrics and increases stability in pleated fabrics. Fused pleating can significantly simplify the sewing process when used in the proper circumstances. This process is also used with suiting in wool boucle and for interfacing. Our machinery gives us the ability to fuse accurately on the roll or in precut fabric blocks.

Product Development

We streamline the process of turning your concepts to reality. Wether it is a skirt, a handbag or a scarf we can help with the design development of your pleated product. We can also work together throughout the whole process from producing pleated samples to production.

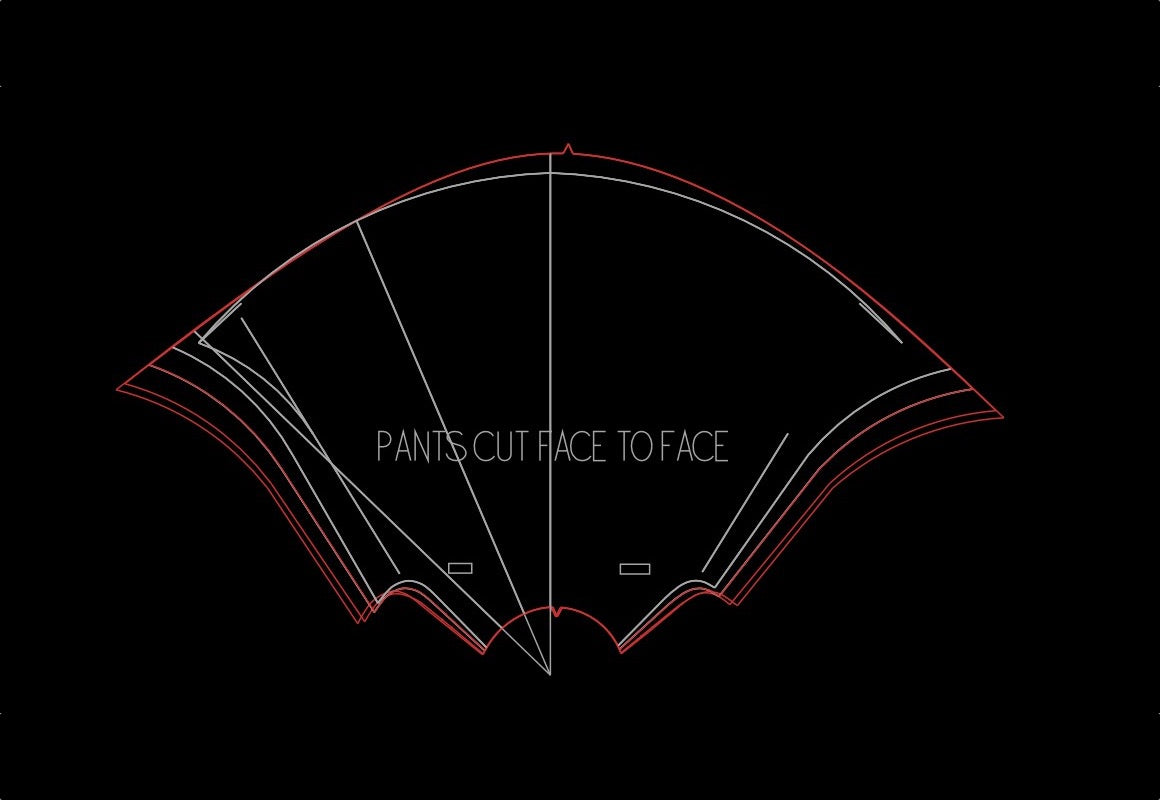

Pleating Pattern Grading

Pleated pattern grading is a service we offer since many of the computerized systems are not programed to do so and there is a general lack of knowledge when it comes to grading for pleating. On many occasions we have saved labor and fabric costs by 50%.

Fabric Shrinking / Sponging

Fabric shrinkage or Sponging is a process in which the fabric becomes smaller (less surface area). This process is performed to “fix” the fabric before the garment is cut in order to minimize unwanted shrinkage during the garment construction process.

CNC Machine Cutting

The CNC machine is a computer controlled robotic cutting machine which allows for more accurate and repeatable cutting. Unlike laser cutting it doesn't burn or create toxic fumes.

Heat Transfer Vinyl

Heat Transfer Vinyl is a speciality polyurethane with a heat-activated adhesive that can be used on certain fabrics to apply designs.

Our specialty equipment gives us the ability to cut larger custom designs and bond larger panels, enabling you to utilize this process beyond a standard T-shirt.

Production Management

In addition to pleated product development, we can coordinate all of the activities between your pattern maker, grader, cutting room and contractor. Ensuring that there are no issues that arise in the production process.

Custom Bridal Development

Let us help you create your dream wedding dress! We can aid in design development, fabric sourcing and, of course, pleating.

Custom Beading

Beading has the ability to enhance the beauty of any fabric or lace it is applied too. We have a large catalog of hand beaded samples that we offer. They are highly customizable. Email Info@internationalpleating.com to set up an appointment.